Why do we need to know how to fix a sewing machine that is not picking up the bobbin thread? Because we can’t sew without a bobbin, not at all.

I wrote a longer post explaining why sewing machines need bobbins and why we can’t sew without a bobbin in its case.

The simplest explanation is that sewing machines need two threads. One is the upper thread, which is also called the needle thread, and the other is the bobbin thread, which is also called the bottom thread.

Thus, we need our machine to pick up the bobbin thread because if we only sew with the upper thread, the thread will be pulled right out as the needle moves. We won’t make any stitches so we won’t be able to do anything.

Check out my reviews for the best thread for sewing machine if you are interested to know which spools you should use both your bottom and top threads.

And you can check out my article on drop in bobbin sewing machines if you want to learn more about this component.

Fixing a Sewing Machine not Picking up Bobbin Thread

Our bobbins are our small spoons of thread. They’re the lower thread. Bobbins can cause a lot of problems from thread breakage, erratic stitching, tension problems and the machine not picking up the thread from them.

If you can’t find what’s wrong with your machine at home, then I recommend taking it to a professional to see what’s the matter.

1. Your hook timing is off

I’m going to start off with what I believe might be the problem for your bobbin thread not being picked up.

Obviously, I can’t tell what is wrong with your machine and its components. That’s what you’ll have to figure out for yourself by eliminating all these causes that I’m going to enumerate. It’s definitely going to be a guessing game.

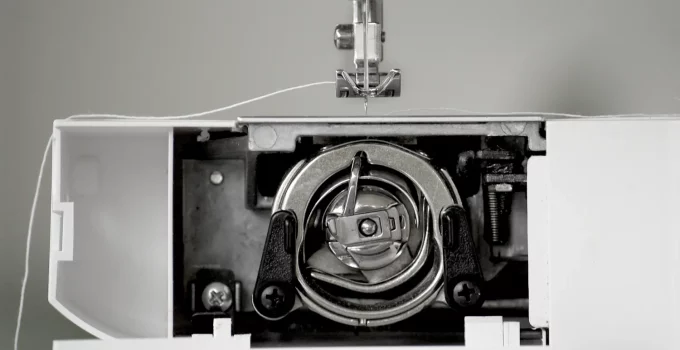

Hook timing is used to describe the relation between the hook tip and the needle eye. Thus, the thread not being picked up might be a timing problem.

Let’s see why the relation between the hook tip and the needle eye is important.

When the needle moves upwards, a loop is created behind the needle, between the needle eye and the fabric. The hook tip passes through that loop and that’s how a stitch is made.

Another easier way to understand what role the hook plays is that the hook basically picks up the thread that the needle brings down.

If the hook timing is off, then the hook rotates up to pick up the thread but the needle is going upwards instead of bringing the thread downwards. They’re out of sync.

And that’s how we end up in the situation of wondering why our sewing machine is not picking up the bobbin thread. Frankly, I think that this might be the problem for most people but I don’t have a way of knowing that entirely.

How to check if the hook timing is off

Remove the bobbin together with its case from the machine so that you can see how the hook functions.

Turn the hand wheel towards you to bring the needle downwards. When you turn the hand wheel towards you and the needle eye goes down, the tip of the hook should be about 8mm from the needle.

The hook moves behind the needle eye at the perfect time when the needle eye is downwards to pick up that thread.

It needs to pick up the thread before the needle goes up. If they’re out of sync you should be able to tell quite easily.

How to fix the hook timing

Frankly, you need a visual guide if you want to fix the hook timing by yourself at home. It involves a few steps that are better explained if you actually see how the fixing is done.

There’s a YouTube tutorial that shows us how we can fix the hook timing at home. I think it does a good job.

There’s another video that shows how it’s done, in case the first one wasn’t of much help.

However, you can also take it to a professional for repairs in case you don’t have the patience.

2. Check the hook tip

Another thing that you should check is the hook tip. We’ve already talked about the importance of the relationship between the hook and the needle eye.

Make sure that the hook-race is properly oiled.

Make sure that the hook and the hook tip are free of damage. The hook tip needs to be sharp and free from burs or nicks.

If the needle has hit the hook, it can damage it and cause burs on the hook tip. Those imperfections can snag and break the thread.

You can inspect the hook by removing the shuttle-hook from the machine if your model has an oscillating hook.

If the hook makes a full circle, then it’s rotary.

If it changes directions, then it’s the oscillating type.

You can find more about these two different hook types here.

3. Check your bobbin

It’s not unusual to come across defective bobbins. These can be defective from the factory. Check out for any imperfections or wrapped edges or bents.

Since the bobbin is a small spool of thread, one imperative function is that it must turn smoothly in its case.

To check that it’s completely functional, roll your bobbin on the table. If it wobbles, it’s worthless. You need a new one.

4. Clean the bobbin case

We get a brush for cleaning parts of our machine. Make sure to keep your case and bobbin tension spring area clean of loose thread or lint.

5. Thread the machine correctly

I’m not going to imply that you don’t know how to thread your sewing machine correctly but everyone makes mistakes, even the most experienced of us.

Plus, beginners should definitely double-check that their machine is threaded correctly if the sewing machine is not picking up the bobbin thread.

If I were you, I would grab a new empty bobbin and I would thread it again. If you’re unsure about the instructions that are included in the user manual for your model, look for a YouTube video. It might be easier.

Also, make sure that the thread is going through the bobbin tension spring.

If this second threaded bobbin still doesn’t make your machine to pick up the thread, then the problem is elsewhere.

6. Thread tails

If the thread tail that comes out of our bobbin is shorter than two inches, then it can get sucked into the machine when we begin to sew or it’s not grabbed by the upper thread.

We need to start with at least 3-4 inches of thread tails.

7. Needle check

This mostly applies to the needle thread (upper thread) but it’s still a good thing to know about because it also involves the bottom thread.

The threaded needle needs to pass through the throat plate and grab the thread from the bobbin case in order to lock the stitch.

If the needle is not being held in all the way, it might not be in the right place to grab the bobbin thread.

Make sure that the needle is not dull or bent.

The needle must also be inserted correctly, all the way into the needle bar before tightening the needle clamp.

Also, make sure to use the right needle size with medium or large size threads. Using a small needle can cause thread breakage.

Check out my guide on how to change the needle on a sewing machine if you need a bit of help.

One last thing that I should mention for this tutorial on why a sewing machine is not picking up the bobbin thread is that you should always turn the hand wheel towards you because if you turn it away from you, you’ll cause a misalignment of the belt and gears.