If you want to operate a well-oiled machine, you’ll need to buy the best sewing machine oil. This is the ingredient you need if you want things to run smoothly and quietly for many years to come.

Sewing machine oil has one main purpose: to ensure that internal components move with the least friction possible.

That’s one way to prolong the lifespan of our sewing machine, whether we have an expensive model or a cheap sewing machine. The price of the machine doesn’t matter. But maintenance and lubrication matters a lot for us sewing machine users and lovers.

There’s one exception to machines that need oiling: self-lubricating models.

Best Sewing Machine Oil: Top 7 Picks

Before oiling your sewing machine, you should make sure to read the user manual that came with it. You should find some type of info in there, like if it comes with oiling holes or it doesn’t require lubrication.

As far as I’m aware, Singer doesn’t have a section on oiling in their user manuals. They only include a section on how to clean the mechanism with a lint brush. I would say that, in that case, you should oil the components where friction is created.

On the other hand, in the user manual for the Brother XM2701, which is a pretty affordable and very popular model, it is mentioned that the machine must not be oiled by the user. The manufacturer mentions that this particular model was manufactured with the necessary amount of oil applied to ensure correct operation.

That’s why you need to read the user manual and then decide if you need to search for the best sewing machine oil or not.

One last thing: avoid using cooking oil or baby oil. Also don’t use WD40, 3 in 1 oil or automotive oil because these have solvent among ingredients.

There are three types of oils that you can use for lubricating sewing machines:

- mineral (petrochemical)

- synthetic (paraffin base stock)

- and natural (coconut or jojoba oil)

Get a good-quality machine oil because it will last a long time. I would call it a worthy purchase.

1. Singer All Purpose Machine Oil

For those who are owners of Singer sewing machines, I’m sure you’ll be interested to check out this machine oil from them.

It’s all-purpose. It’s definitely not created only for Singer models, it works for all brands.

Besides sewing machines, this specially formulated lubricant also works for knitting machines, vacuum cleaners, typewriters, computers, bicycle gears, and other household appliances.

It’s a 4 oz. bottle that is also very cheap. It is totally worth it as the best sewing machine oil. Everything about this product is just the way it should be: quality, price, size, utility.

However, it wouldn’t be a proper review if I didn’t mention at least a con. It has a short nozzle. It’s good enough for the needle bar and the bobbin assembly but it’s not exactly the best option for those who want to take their sewing machine apart and lubricate even harder to reach places.

If you don’t plan on removing the underside, topside, right side, front side, back side and other access panels, then you won’t have any problems when using the Singer All Purpose Machine Oil for basic lubrication.

2. Liberty Oil

This is a perfect oil for lubricating the entirety of a sewing machine’s moving parts because it comes with a stainless steel needle tip dispenser.

The needle dispenser will be able to reach all of the dry parts of your machine, even if you want to take it apart quite thoroughly for an intense maintenance and lubrication.

This is a 1.5 inches 18-gauge stainless steel needle tip that is of pharmaceutical grade with patented Luer lock cap to insure no leaks.

Moreover, what truly matters is that oil is blended from the finest high viscosity index solvent refined hydro-finished 100% pure paraffin base stocks available.

Thus, this is a synthetic oil for sewing machines. It’s really great. The other option you can use as the best sewing machine oil is mineral oil, which is petrochemical.

Liberty Oil is easy to use not only because it’s capable of reaching all places but because the bottle is made of very soft plastic that is easy to squeeze.

The bottle is pretty small, 1 oz.

The price is a bit expensive but it’s of the highest quality. I would say that it’s an amazing choice if you’re looking for the best sewing machine oil and you don’t mind spending a bit more on a small bottle.

3. Dritz Sewer’s Aid

This is a small bottle of 0.5 oz. Given the quantity, you might think that the price is a bit high. Let’s see what it offers.

I should also let you know that Dritz is a very good manufacturer of French curve rulers. You’ll have to see if that applies to their machine oil, too.

It is a clear non-staining lubricant that can be applied to our hands and it can also be used on sewing machine needles for smoother and easier penetration into the fabric.

Moreover, we can also use a drop on spool and bobbin thread to lubricate the machine.

Applying a small amount of Dritz Sewer’s Aid on the bottom of the presser foot helps it glide over the fabric.

You can also use it on scissor blades for smooth cutting action.

Thus, the immediate conclusion we can draw is that this is much more than an oil for sewing machines.

It works on our hands, on our needles to help them penetrate the fabric more easily, and on spool and bobbin thread.

People also use it for feeding thread into the machine. It also helps with breakage and shredding, especially for embroidery.

Users also mentioned that it can also aid in preventing the sewing machine from skipping stitches when it’s stitching together several layers of fabric.

Thus, even if you get Dritz Sewer’s Aid, you’ll still need a separate best sewing machine oil, like the ones from Singer or Liberty Oil that I recommended above.

Dritz Sewer’s Aid is a good lubricant but, as I’ve mentioned above, it has other purposes.

4. Lily White Sewing Machine Oil

What makes this Lily White Sewing Machine Oil completely different is the quantity.

If you’re in the mood to buy a 1 gallon of sewing machine oil, this is the product for you.

It’s a low viscosity, water white lubricating oil for sewing machines, textile machinery, and parts. Some people also buy this one to use it as bike chain oil since it comes in such an impressive quantity.

What more can I say?

It works, it’s delivered in a 1 gallon bottle, and it won’t stain your projects if you happen to get a few drops on the fabrics. It’s really great.

5. Juki Defrix Oil: Best Sewing Machine Oil for Professional Use

It’s delivered in a 600ml bottle because it’s imported from Japan. That’s the equivalent of about 20 oz. It’s a large bottle that is sold for a good price, considering its quality.

However, it mentions that it’s for professional use only, meaning it’s great for industrial sewing machines.

Owners of industrial Juki sewing machines should only use this product for lubricating their machines.

Machines like the Juki TL-2000Qi and Juki TL-2010Q are sold with a bottle of this oil among accessories.

6. Supco Zoom Spout

This is described as a multi-purpose precision oiler.

It also comes in a 4 oz. bottle so we get a good quantity to last us quite a while, even if we want to lubricate more than our sewing machines.

What I really like about this Supco Zoom Spout multi-purpose precision oiler is the very long, flexible spout. It also extends and retracts to any in-between length. This type of spout is perfect if you want to reach any dry mechanism.

It is a paraffin base, non-gumming, high-quality lubricating oil. That tells us everything we need to know.

I love the multi-purpose aspect but you can certainly pick the Supco Zoom Spout as the best sewing machine oil. You’ll love it.

7. Tri-Flow TF2006 Superior Lubricant

Tri-Flow has some amazing lubricants for a wide variety of parts, mechanisms, and machines.

It’s also quite well-known as a very good choice for sewing machines.

I generally prefer the Tri-Flow 12 oz. Aerosol when it comes to sewing machines because it’s just so easy to use. If you’ve taken your machine to a dealer, you might have seen the personnel there using Tri-Flow to oil all kinds of models.

The aerosol spray action reaches all the needed areas for a quick and easy application. You press once and that’s it.

The high-grade petroleum oils provide optimal lubrications, even under extreme temperatures and humidity.

Moreover, the formulated solvents soften and remove first. The special additives displace moisture and prevent rust and corrosion.

These features will come in handy for those who are trying to restore old sewing machines that have their mechanism stuck.

Once the Tri-Flow does its job, the machine will move easily, even if it’s a restored model.

How to Clean a Sewing Machine Short Guide

We’ve seen which are the top options for the best sewing machine oil. Now, it’s time to go into details about maintaining a sewing machine properly.

The first thing you need to think about is cleaning your machine. That comes before oiling it.

When we’re doing our stitches for our wonderful projects, when the needle punctures the material, lint is left behind in the bobbin mechanism.

That shed lint, if it’s left in the mechanism, will be mixed together with machine oil. That will create a nasty mix that can get caught in the gears, which can eventually make them stop moving.

Thus, you can easily avoid such complicated problems and prolong the life of your model by a routine cleaning.

You’ll need a dusting brush, cotton swabs, cotton rag, rubbing alcohol, and screwdriver. The screwdriver is always included among accessories for a reason, for you to use it quite often for maintenance.

Some sewing machines will even include a lint brush among accessories for cleaning the machine.

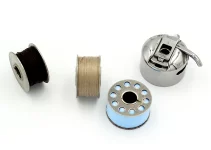

In order to clean it, remove the needle, presser foot, and shank. Take out the bobbin case and bobbin hook assembly.

Take out the screws (make sure not to lose any).

Use the brush to clean out the lint and dust from the entire area.

Use cotton swabs and rubbing alcohol to clean all these components: bobbin case, hook, needle bar, and everywhere else.

Lastly, use the cotton rag with rubbing alcohol to wipe the machine shell and bed. Also use it to swipe between tension disks.

Rubbing alcohol is perfect for cleaning a sewing machine because it evaporates quickly and doesn’t lead to rust.

What part of the sewing machine needs oil?

The tools needed for lubricating a sewing machine are: the best sewing machine oil, cotton rag, and screwdriver.

The parts of the sewing machine that need oiling are:

- needle bar

- bobbin assembly (bobbin area after removing the bobbin case)

You just need a drop of oil for each of these components. Then wipe off the excess with the cotton rag.

For the needle bar, turn the handwheel until the takeup lever is in its highest position. Put a drop of oil on the needle bar where it goes down into the shaft and then turn the handwheel. When the bar is down, the oil will pool on the shaft.

The same goes with the bobbin assembly. Put a drop of oil and then turn the handwheel to distribute it.

If you are inclined to take it up further, you can remove the underside as well as the topside to oil all surfaces that look dry. You can also remove the right side, front side, back side and other access panels to see if there are dry surfaces in need of lubrication. But that’s certainly something that not a lot of people do at home.

The parts on a sewing machine that should never be oiled are: plastic/nylon parts or gears.

There are also plenty of YouTube videos that will teach you how to remove the parts, oil them, and put them back together.

How often should I oil my sewing machine?

There’s no direct answer. Some will say that you should oil it a couple of times per week if you use it daily.

I would say that’s too often for most people, unless you’re a professional.

If you’re a professional, maybe you even oil it before every project.

If you’re an amateur that doesn’t use its machine for many hours a day, every single day, then even lubricating it once every 3-4 months is more than enough.

Does a Singer sewing machine need oil?

There is only one exception to sewing machines that don’t need oiling: models that are sealed and self-lubricating.

If your Singer machine doesn’t mention that it’s self-lubricating, then you’ll need to oil it as part of its maintenance.

Cleaning and lubricating the parts that I mentioned above applies to pretty much all sewing machine brands, whether we’re talking about Singer, Janome, Juki etc. or we’re talking about mini-sewing machines.

Frankly, most Singer user manuals don’t even have a section where they mention oiling. But they don’t say that those models are self-lubricating or that you shouldn’t oil them at all.

Since Singer also have their own all-purpose oil, I’m pretty sure that it’s another indication that, in general, Singer sewing machines need oil.

My rule is that I oil all the parts where friction is created if the manufacturer doesn’t explicitly mention that a particular model shouldn’t be lubricated. Most don’t and that’s why we need to search for the best sewing machine oil.